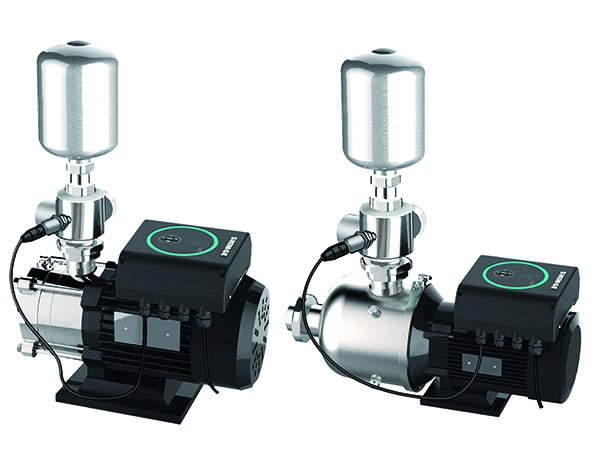

Features of stainless steel booster multistage centrifugal pump

1. The stainless steel multi-stage pump adopts excellent hydraulic model and advanced manufacturing process, which greatly improves the performance and service life of the pump.

2. Since the shaft seal adopts the mechanical seal made of hard alloy and fluorine rubber, the reliability of the pump operation and the temperature of the conveying medium can be improved.

3. The overflow part of the pump is made of stainless steel plate by stamping and welding, which makes the pump suitable for mildly corrosive media.

4. The overall structure is compact, small in size, light in weight, low in noise, energy-saving, and convenient for maintenance.

5. The water inlet and water outlet of the pump are located on the same horizontal line of the pump base, which can be directly used in the pipeline.

6. Using standard motor, users can easily equip the motor according to their needs.

7. It can be equipped with an intelligent protector according to user needs, which can effectively protect the pump from dry running, phase loss, overload, etc.

The fluid may be a liquid, gas, or a solid-liquid mixture. Centrifugal pumps are classified as single stage or multi-stage depending on the number of impellers they have. Single stage centrifugal pumps have one impeller and are used for applications where low heads (delivery pressures) are required. Multi-stage centrifugal pumps have two or more impellers and are used for applications where high heads are required.

Stainless steel multi-stage centrifugal pump advantage

Stainless steel multi-stage centrifugal pump is widely used in water supply and drainage engineering, fire fighting system, long-distance water transportation, heating system, circulating cooling water system and shipbuilding industry. It has the advantages of small size, light weight, convenient operation and maintenance, etc.

The advantage of the stainless steel multi-stage centrifugal pump is that it can be used for a wide range of applications, including those in which corrosive or abrasive fluids are present. Additionally, these pumps are able to operate at high pressures and temperatures, making them ideal for use in demanding industrial environments.

Multi-stage centrifugal pumps have many advantages over single-stage pumps. They are able to generate higher pressures and they are less likely to cavitate. Multi-stage pumps also have a smaller footprint and they are more energy efficient.

But What the difference between multi-stage centrifugal pump and single-stage centrifugal pump?

Before know the difference, we should know What is a multistage centrifugal pump, and What is a single stage centrifugal pump? Then We will know the difference between a multi-stage centrifugal pump and a single-stage centrifugal pump? This is what everyone wants to know about centrifugal pumps.

The single-stage centrifugal pump is a flowing body and liquid, or a mixture of suspended particles and gas or liquid. It enters at the entrance of the root of the blade shaft, and relies on the rotating blade to obtain a centrifugal force, and then generates high pressure, which flows out from the pressure relief outlet. of these media conveying devices.

The multi-stage centrifugal pump is a collection of two pumps with the same function. In terms of the structure of the fluid channel, its performance is that the medium pressure relief port of the previous stage and the inlet of the latter stage can communicate with each other. , In this way, at the entrance of the layers, the pressure relief port and the entrance are all figured out, so that the series structure forms a multi-stage centrifugal pump. The function of setting a multistage centrifugal pump is to increase the set pressure.

The single-stage centrifugal pump includes the pump body, the pump cover, the motor device with the output shaft, the pump shaft, the bearing seat, the impeller, the mechanical seal and the mechanical seal gland structural components installed in the pump body. The key feature is that it contains There is a device between the output shaft of the motor and the pump shaft called a wafer coupling, or a device installed on the bearing seat, called a guide bearing that helps to support the pump shaft.

What is the difference between a multi-stage centrifugal pump and a single-stage centrifugal pump

Experts tell us the difference between multi-stage centrifugal pumps and single-stage centrifugal pumps, the focus is on the number of impellers. Multistage centrifugal pumps are characterized by high pressure and low flow. The single-stage centrifugal pump has only one stage of impeller, which is characterized by low pressure and large flow.

First, the single-stage pump refers to a pump with only one impeller, and the highest head is only 125 meters.

Second, the multi-stage pump has two or more impellers, and the highest lift can exceed the lift of the single-stage centrifugal pump; when the multi-stage pump has a single-stage pump lift, it is necessary to add two-stage motors. By increasing the number of impellers to use a four-stage motor, the service life of the pump can be increased and the noise of the unit can be reduced, but the maintenance of multi-stage pumps is a bit more difficult than that of single-stage pumps.

Third, when the actual lift required by the pump does not exceed 125 meters, the multi-stage pump is generally more expensive according to the area of the pump studio and the price of the pump, and various reasons should be considered together. The single-stage pump should be selected. The pump is also a multistage pump.

Fourth, because there is only one impeller on the pump shaft of the single-stage centrifugal pump, and there are many impellers connected in series on the pump shaft of the multi-stage centrifugal pump, the multi-stage centrifugal pump is installed on the same shaft by impellers above two stages. Okay, let’s work together to rotate. The output of the front impeller enters the input of the rear impeller, and each layer of impeller blades is installed, which is called the first stage.

Installing more than two pumps is called a multi-stage centrifugal pump, so a single-stage pump is only installed with an impeller. In the installation method, this is the biggest difference from the metering diaphragm pump.

Stainless Steel Multi-stage Centrifugal Pump Manufacturer

As a Stainless Steel Multi-stage Centrifugal Pump Manufacturer, We have a domestic high-level pump performance test center, and its products all adopt advanced design methods such as CAD design software and CFD computational fluid dynamics software.

Our products have gone through more than ten processes such as precision casting, hot forging, welding, heat treatment, finishing and assembly. Advanced CNC machining center, plasma welding machine, full-automatic gas protection, semi-automatic vacuum welding machine, ultra frequency vacuum heat treatment equipment, efficient processing special machine, physical and chemical and flaw detection equipment and other high-precision processing detection equipment are used.

The complete processing and testing equipment is in a leading position in our Stainless Steel Multi-stage Centrifugal Pump Manufacturer, which fully guarantees the quality of products.

In addition, Shoufei Pump, A Stainless Steel Multi-stage Centrifugal Pump Manufacturer also has a perfect integrated service system: including early professional technicians to quickly answer various technical inquiries, respond to your needs, select appropriate products for you, and provide reasonable and reliable suggestions; Commitments on product quality, supply cycle, etc., and provide specific product plans and quotations.

After sales includes: providing product installation, use, maintenance, troubleshooting and other services. Welcome new and old customers to visit and negotiate business. We will continue to work hard to provide you with quality products and services.