Pumps are commonly used in a variety of industries, from agriculture to manufacturing. They are essential tools for transferring liquids, gases, and other materials. Pumps can be used to move water, oil, chemicals, fuel, and more. In industrial settings, pumps are used to drive machinery and process materials. They can also be used to create pressure or vacuum inside a system.

Pumps come in many shapes and sizes, depending on the application. Some pumps are small enough to fit in the palm of a hand while others may be large enough to fill an entire room. Industrial pumps can range from simple hand-operated pumps to complex electric or hydraulic systems. Depending on the application, different types of pumps may be used including centrifugal, displacement, or positive displacement pumps.

In addition to their industrial applications, pumps are also commonly used in residential settings for water supply and drainage. Pumps are designed for various purposes such as supplying water for domestic use or transferring wastewater out of a house. Pumps come in both electric and manual versions depending on the needs of the user.

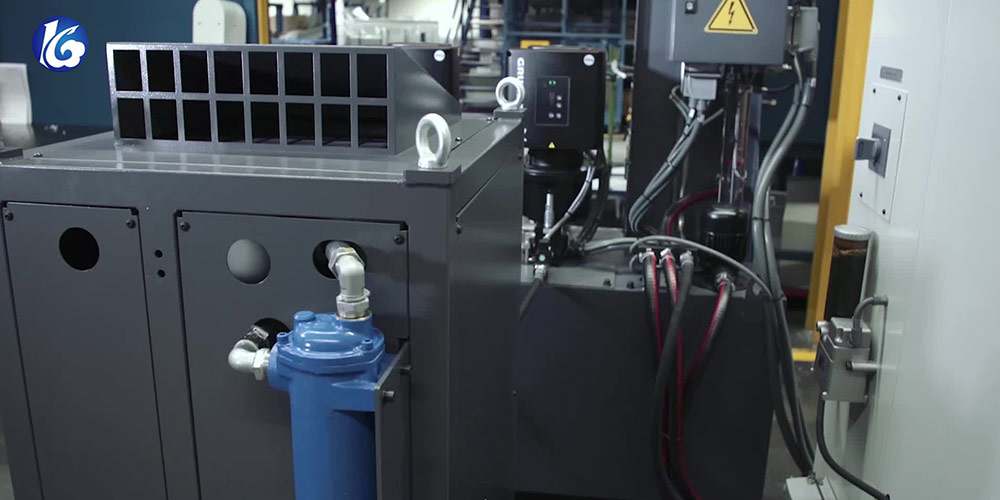

High pressure coolant pumps for CNC machines are an essential part of a well-functioning machine. These pumps help ensure that the fluids used in CNC machines run efficiently and effectively. With the right pump, CNC machines can operate with maximum efficiency and precision. High pressure coolant pumps provide a consistent amount of pressure so that the coolant is evenly distributed throughout the machine.

This helps reduce wear and tear on the components, allowing them to last longer. Additionally, these pumps can also help reduce noise levels and improve performance. When using a high pressure coolant pump for CNC machines, it is important to select one that meets the specific requirements of the machine. This ensures that it is compatible with the machine's other components and will provide optimal performance.

High pressure coolant pumps come in a variety of sizes and configurations, depending on the type of CNC machine being used.They are capable of providing a wide range of pressures necessary to keep the CNC machine running at peak efficiency. Additionally, these pumps are designed to be easy to install and maintain, making them a great choice for any CNC setup.

Cooler transfer pumps are an important tool for cooling systems. They can help keep your system running at an optimal temperature, which can make all the difference when it comes to performance. With a cooler transfer pump, you can move coolant from one part of the system to another, ensuring that all parts of your system are adequately cooled. This can help reduce the risk of overheating and improve the longevity of your parts. These pumps are easy to install and use, making them a great choice for those looking for an efficient and effective way to keep their system running smoothly.

A cooler transfer pump is a device used to move liquids from one container to another. It is often used to transfer liquids from large containers to smaller containers and can be used to transport a variety of different liquids.

A machine tool cooler pump is an essential component in any workshop. It helps to keep the machinery cool and running efficiently. This type of pump is designed to circulate coolant through the machinery, ensuring it doesn't overheat and break down. The cooler pump provides a steady flow of coolant, maintaining temperatures at optimal levels. It also helps to reduce vibration and noise, making the workshop environment more pleasant for workers. Investing in a quality machine tool cooler pump will help ensure your machinery runs safely and efficiently for years to come.

A machine tool cooler pump is an important component of a manufacturing process. It helps to keep machines running at optimal temperatures and prevents them from overheating. The pump works by circulating coolant, typically a water and oil mixture, throughout the system.

Industrial cooler pumps are essential machinery for industrial cooling systems. They are a reliable and efficient way to keep temperatures at optimal levels in many different types of industrial settings. With their powerful motors, these pumps can efficiently circulate coolant through the system, ensuring that temperatures remain controlled. They are available in a variety of sizes and configurations to suit different types of applications.

Industrial cooler pumps are easy to install and maintain, and they come with a range of features to meet the needs of any industrial cooling system. They are an invaluable asset to any business, providing reliable temperature control and peace of mind.

A machine cooler pump is an essential device that helps keep machines cool and running efficiently. It works by circulating cooling liquid through the system, which helps to dissipate heat and maintain a safe temperature for the components. The pump consists of a motor, impeller, casing, and other parts, all of which work together to move the liquid throughout the system. By ensuring that the components in a machine stay at a controlled temperature, the machine cooler pump helps to extend its life and ensure its proper functioning.

A machine cooler pump is an essential piece of equipment for many industrial and commercial applications. It is used to move large amounts of liquid or gas from one location to another. The pump works by creating a vacuum that sucks the liquid or gas through a tube, which then passes the material to another part of the system.

Zhejiang Shoufei Pump Industry Co., Ltd.is a domestic professional stainless steel multi-stage centrifugal pump manufacturer integrating scientific research, manufacturing and sales. Since its establishment, the company has taken "integrity and innovation" as the company's development goals, and has provided customers with professional and fast first-class services for the purpose. The company has established a sound marketing network, and now the products have been widely used in a wide range of areas.

Company leading products

Shoufei company's leading products are: CDL&CDLF series vertical multi-stage centrifugal pumps, TD pipeline circulation pumps, CDLK series immersion multi-stage centrifugal pumps, constant pressure & non-negative pressure water supply equipment, pump parts and many other products, performance indicators and technical parameters have reached to the advanced level, which can meet you any requires in water supply systems.

Address : No. 2, Xiayang Industrial Zone, Deqing County, Huzhou City, Zhejiang Province, China.

Email : sales@shoufeipump.com Mobile: +86-136-6574-2262 Phone: 86-0572-8355383