How to install horizontal single stage centrifugal pump

1. Check the manufacturer's instructions for specific installation requirements and recommendations.

2. Mount the pump on a flat, level surface using the base plate or foundation bolts provided by the manufacturer.

3. Connect the inlet and outlet piping to the pump, following the manufacturer's recommendations. Use pipe unions or flanges to make connections, if required.

4. Install a check valve in the inlet piping to prevent backflow when the pump is not in operation.

5. Fill the pump with clean water, following the manufacturer's instructions. Prime the pump if necessary.

How to install horizontal single stage centrifugal pump

1. Check the inlet and outlet of the pump for any blockages.

2. If the inlet is clear, check the outlet. If the outlet is also clear, check the suction line for any blockages.3. Once you have confirmed that there are no blockages, start the installation process by attaching the pump to the suction line.

4. Make sure that all connections are secure before continuing.

5. Next, attach the discharge line to the pump and again, make sure all connections are secure.

6. Finally, fill the pump with water and turn it on to test it out.

How to maintain horizontal single stage centrifugal pump

1. Inspect the pump regularly.

2. Check the pump’s alignment.

3. Lubricate the bearings regularly.

4. Keep the pump clean.

5. Check the wear on the impeller and other moving parts.

6. Inspect the seals and gaskets regularly.

A centrifugal pump is a mechanical device used to transfer fluids by using centrifugal force. It consists of a rotating impeller that creates a vacuum, which draws fluid in. The fluid is then discharged at high pressure. Centrifugal pumps are used in many industries, including oil and gas, power generation, water and wastewater treatment, and chemical processing.

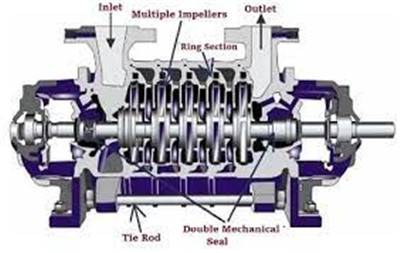

There are two main types of centrifugal pumps: single stage and multi-stage. Single stage pumps have one impeller, while multi-stage pumps have multiple impellers.