The main function of inline centrifugal pump

The main function of an inline centrifugal pump is to transfer fluids from one place to another. This is accomplished by using a rotating impeller to create pressure and move the fluid. The impeller is driven by an electric motor, which runs at a predetermined speed. Inline centrifugal pumps are commonly used in many industries, such as oil and gas, water treatment, and chemical processing. They are also used in residential applications, such as sprinkler systems and hot water circulation. Inline centrifugal pumps are typically smaller than other types of pumps, making them easier to install in tight spaces. They are also more efficient than other types of pumps, resulting in lower operational costs.

The main function of an inline centrifugal pump is to move liquid from a low pressure zone to a higher pressure zone. This type of pump works by transferring energy from its rotating impeller to the liquid, thereby creating a suction that draws the liquid into the pump. The rotating impeller then pushes the liquid out at a higher pressure. Inline centrifugal pumps are commonly used in industrial and commercial applications such as water supply systems, air conditioning systems, agricultural irrigation systems, and many other applications where a consistent flow of liquid is needed. The durability of this type of pump also makes it popular in many industries due to its ability to withstand extreme temperatures and pressures.

About horizontal multistage centrifugal pump

A horizontal multistage centrifugal pump is a type of pump used for transferring liquids from one place to another. It is powered by an electric motor and uses centrifugal force to push the liquid through the system. This type of pump is especially useful for applications where a high pressure is required, such as in water supply systems, firefighting systems, and industrial processes. The horizontal multistage centrifugal pump has several stages, each of which helps to increase the pressure of the liquid being pumped. The stages consist of impellers and volutes, which are designed to maximize the efficiency of the pump. The impellers create a centrifugal force that pushes the liquid through the volutes and out of the discharge pipe. This type of pump is highly efficient and reliable, making it ideal for many applications.

A horizontal multistage centrifugal pump is a type of pump that uses centrifugal force to move liquids from one place to another. It is composed of multiple stages which operate in sequence, with each stage increasing the pressure of the liquid. This type of pump is commonly used for industrial and agricultural applications, as it can be used to move large volumes of liquid quickly and efficiently. The main advantage of this type of pump is its ability to handle high pressures, making it suitable for applications that require high pressure pumping. Additionally, its compact design allows for easy installation and maintenance.

About horizontal end suction centrifugal pump

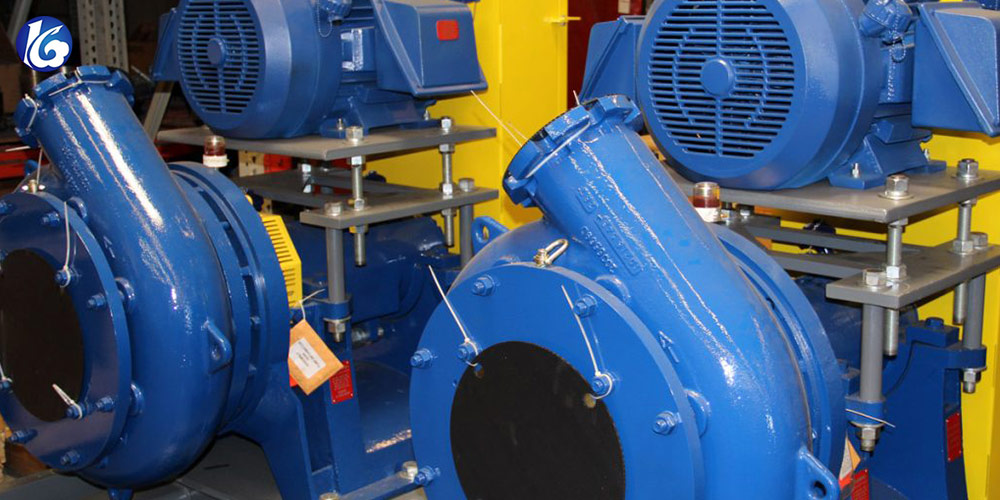

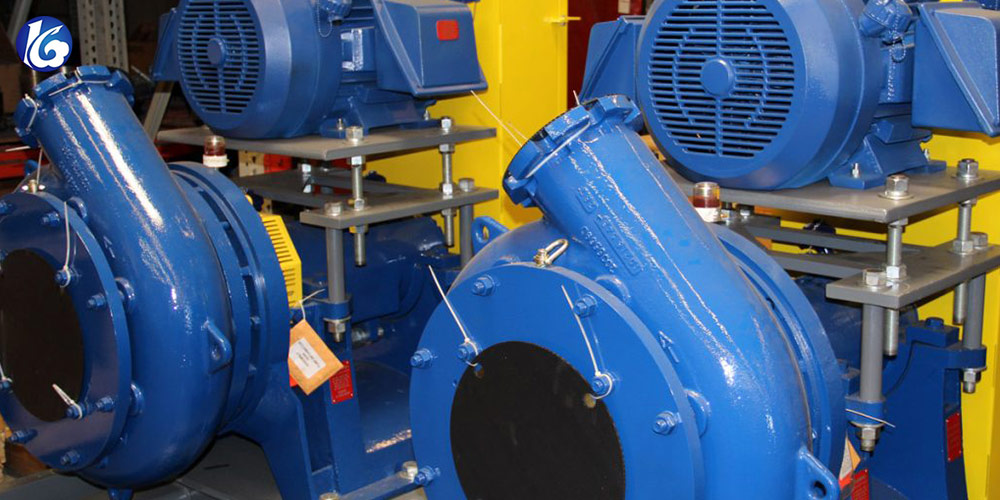

A horizontal end suction centrifugal pump is a type of pump commonly used in a variety of industrial and commercial applications. It is designed to draw liquid from an intake and discharge it at a high pressure using the centrifugal force created by the impeller. This type of pump is popular due to its relatively low cost, ease of installation, and ability to handle a wide variety of liquids. It is often used in water supply systems, cooling towers, irrigation systems, and fire-fighting systems. The pump can be mounted horizontally or vertically depending on the application. It also has adjustable speed control capability which allows for greater efficiency and reliability.

A Horizontal End Suction Centrifugal Pump is a type of pump typically used in industrial and agricultural applications. It is designed to move fluids, such as water, lubricants, and chemicals, from one area to another. This pump consists of an impeller and a volute casing which rotates at high speeds to create the necessary pressure for pumping the liquid. The impeller draws in the liquid at one end and then forces it out through the other end in a continuous process. The suction side of the pump is usually placed on the horizontal axis for easier maintenance and to reduce noise. This type of pump is usually highly efficient, reliable, and cost effective.